Siehe F1 Power

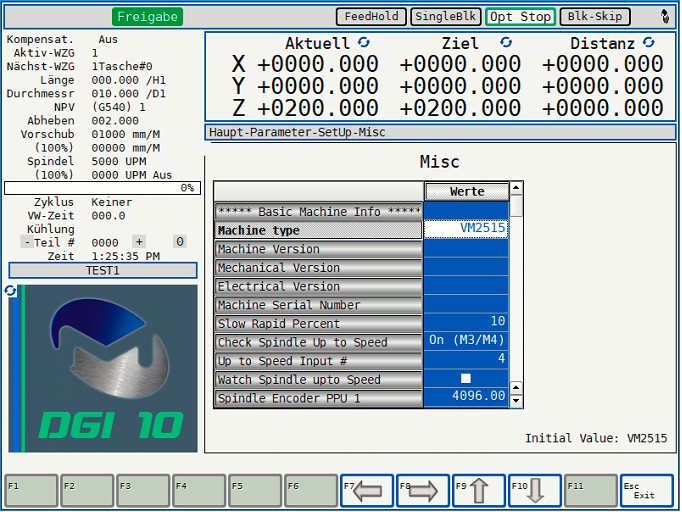

| ***** Basic Machine Info ***** | *****Maschinen Informationen***** |

| Machine type | Maschinenmodell |

| Machine Version | Maschinen-Version |

| Mechanical Version | Mechanik-Version |

| Electrical Version | Elektro-Version |

| Machine Serial Number | Serien-Nummer |

| Slow Rapid Percent | Anzeige Eilgang Prozent |

| Check Spindle Up to Speed,Off,On (M3⁄M4),From Rapids to Feeds | Prüfe Spindeldrehzahl UPM erreicht |

| Up to Speed Input # | Input # UPM erreicht |

| Watch Spindle upto Speed | Beobachte UPM erreicht |

| Spindle Encoder PPU 1 | Pulse Spindelencoder 1 |

| Spindle Encoder PPU 2 | Pulse Spindelencoder 2 |

| Handwheel Encoder PPU | Pulse Handrad Encoder |

| Spindle Range 1 | |

| Spindle Range 2 | |

| Spindle Range 3 | |

| Spindle Range 4 | |

| Spindle Range 5 | |

| Spindle Range 6 | |

| Spindle Range 7 | |

| Spindle Range 8 | |

| Spindle Range,Scaled,1,2,3,4,5,6,7,8 | |

| Maximum Spindle Speed | |

| Spindle Ramp Time 1 (sec) | |

| Max Spindle Motor RPM | |

| Gearbox Ratio Low | |

| Gearbox Ratio High | |

| Spindle Ramp Time 2 (sec) | |

| Spindle Ramp Time Top (sec) | |

| Tap Up Double | Gewindebohrer rückwärts doppelte Drehzahl |

| 2 Gear Yaskawa M5 Spndle Motor | |

| Electronic Spindle Gears | |

| Spindle Gear Box | |

| Hard Tap Fudge Factor | |

| Feedback on Quill Scale | |

| Quill Epsilon | |

| Quill Scale Encoder | |

| Quill Scale Ppu | |

| Back Gear Reverse | |

| AC Brushless Axis Motors | |

| Check Air Pressure | Prüfe Luftdruck |

| FeedHold Input | |

| Check Tool Door Open | Prüfe Tür offen |

| European Code | EU Code |

| European Code Delay | |

| Euro Code Max Feed (ipm) | |

| Euro Code Rotary Max Feed | |

| Euro Code Max Spindle RPM | |

| Euro Code Door Delay | |

| Euro Code Enable Toggle | |

| Chiller Fault Input # | Spindelkühler Fehler Input# |

| Cool-down time (min) | Abkühlungszeit ( min ) |

| Lube Cycle Time (min) | Schmierzyklus ( min ) |

| Grease Cycle Time (hour) | |

| Grease ESTOP Time (sec) | |

| Way Lube On Time (sec) | Schmierung Führungen an ( Sek ) |

| Way Lube Off Time (min) | Schmierung Führungen aus ( min ) |

| Recycle Pump Time (sec) | Füllpumpe IKZ ( Sek ) |

| Coolant Thru Spindle,None,Low Pressure,High Pressure,ChipBlaster,Milltronics⁄CTS-Ready | |

| Auto Door Open | |

| Aux1 Button Function | |

| Spindle Probe | |

| Probe Input # | |

| Cranking Minutes⁄Rev | |

| Cranking Factor | |

| Cranking Max IPM | |

| Max Corner Dev | |

| G187 Max Corner Dev | |

| G188 Max Corner Dev | |

| G189 Max Corner Dev | |

| Always stop if corner is:,90 degrees,60 degress | Achsen immer anhalten wenn Ecke: 90° ⁄ 60° |

| Min Block Time (sec) | |

| Tri-Color Cycle Light | |

| Cycle Light Output # | |

| Cylinder Parked Axis | |

| Cylinder Rotary Axis | |

| Data Log Input # | |

| Data Log Path,Parts,Network | |

| Data Log Network Folder | |

| ***** Software Options ***** | ***** Software Optionen ***** |

| Allow Modal Restart | Neustart ⁄ Wiederaufnahme des Programmlaufs mit Abfrage der Bedingungen |

| Allow Away Offset | Erlaube WZG-Versatz Korrektur während Programmlauf |

| Look Ahead Blocks | |

| Look Scope Blocks | |

| Transition Radius | |

| G187 Transition Radius | |

| G188 Transition Radius | |

| G189 Transition Radius | |

| Small Move Multiplier | |

| Max solid graph size | |

| Graph Look Ahead | |

| G18 is,XZ plane,ZX plane | |

| G93 is,1⁄min,1⁄sec | |

| Special Flags | |

| G5#-Z in HandWheel | G5#-Z Achse in Handrad |

| Tool Setting,Current Tool,Any Tool | WZG abnullen: Aktuelles WZG, Jedes WZG |

| Tool Setting, Use Work Offsets | WZG abnullen: berücksichtige NPV |

| Z Tool Setting touch off | |

| 90 degree Cutter Comp | 90° Fräser-Radius-Kompensation ( FRK ) |

| SingleBlock thru CannedCycles and TCs | |

| Don't show line# for current block | |

| 2nd On Pocket Prox Input # | |

| Cpu Warning Temperature | |

| ***** Cad Parameters ***** | ***** CAD Parameter ***** |

| CAD Type is,DXF,IGS | |

| CAD Epsilon | |

| ***** Post M codes table ***** | |

| Post Mcode #0 | |

| Post Mcode #1 | |

| Post Mcode #2 | |

| Post Mcode #3 | |

| Post Mcode #4 | |

| Post Mcode #5 | |

| Post Mcode #6 | |

| Post Mcode #7 | |

| Post Mcode #8 | |

| Post Mcode #9 | |

| ***** Spndl Power Monitoring ***** | ***** Spindel Leistungsüberwachung ***** |

| Spindle Power Raw | |

| Spindle Power Scale | |

| Spindle Power (Torque %) |